History

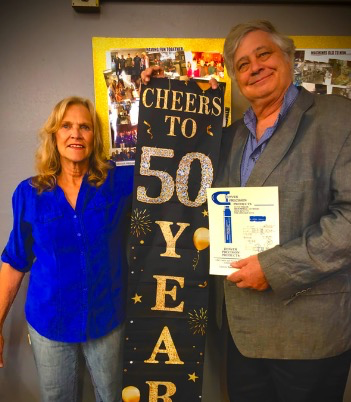

In 1922, Grandpa Claude A. Knuepfer began his journey in the world of manufacturing. After WWII his two sons, Jack Knuepfer and Bob Knuepfer, continued the legacy in manufacturing by settling into the world of turning. (Cam operated screw machines at the time) Both sons grew their businesses. Today, there are shops that span multiple states and service many different industries. Denver Precision Products was originally opened by Jack Knuepfer but soon after, the torch was passed to the next generation Claude F. Knuepfer.

Bottom left: brother Paul above him Jack Knuepfer second president of company in Chicago and the founder of Denver Precision Products: above him Claude A. Knuepfer first president of Chicago company and to his right Henry Knuepfer father of Claude A. In his lap Claude F. Knuepfer, current president of Denver Precision Products

In college, Claude argued that the reason why America was lagging behind the rest of the industrial world was because of the cost to replace and modernize with current technology . In the 1980s Claude realized Denver Precision was no different because we were still running machines from the 1950’s.

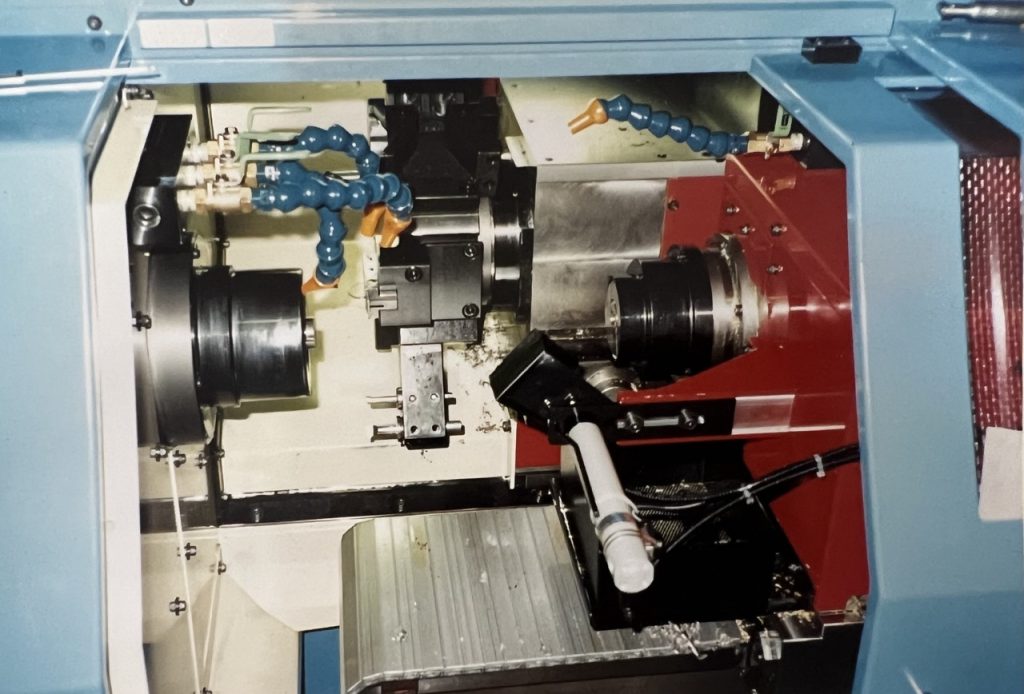

In the 1980s a new era was born for Denver Precision Products with the first investment in a Computer Numerical Controlled (CNC) machine. By accepting the change from cam operated machinery to CNC this allowed new heights of precision and innovation. A part that took 2, 3 or 4 operations will now only take one operation with sub spindles, pinch turning, live tooling, etc. This vastly improves the quality and efficiency of running production parts.

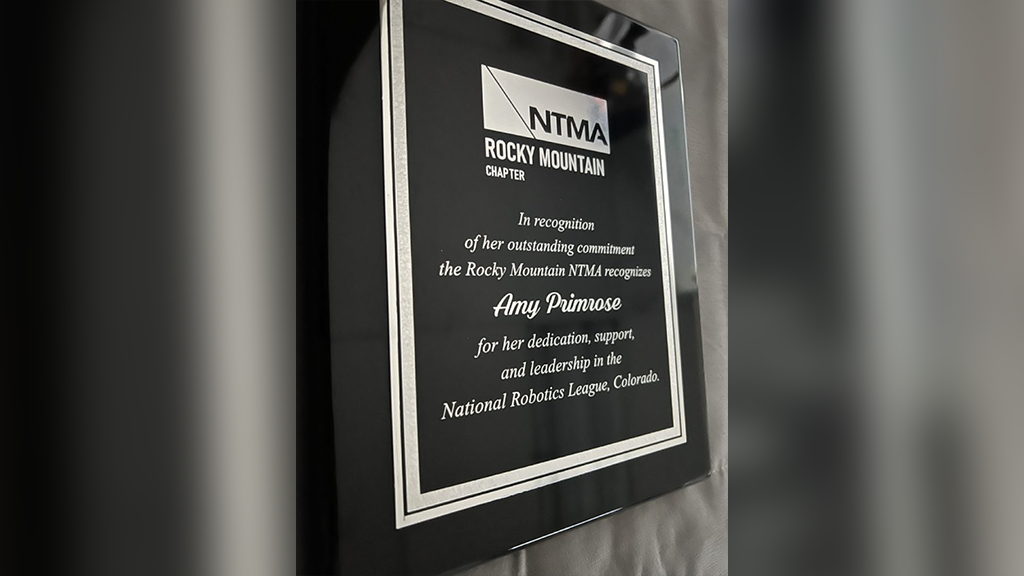

Today, Denver Precision Products is again in a transition phase from one generation to another. Jacob Knuepfer and Amy Primrose, a brother-sister duo, are looking to the future while maintaining quality services to our customers. We will continue to grow our technology and invest in automation to help our customers grow. Denver Precision Products looks to its history to grow the future. We continue to be involved in machining associations and the community in order to keep manufacturing in the USA.